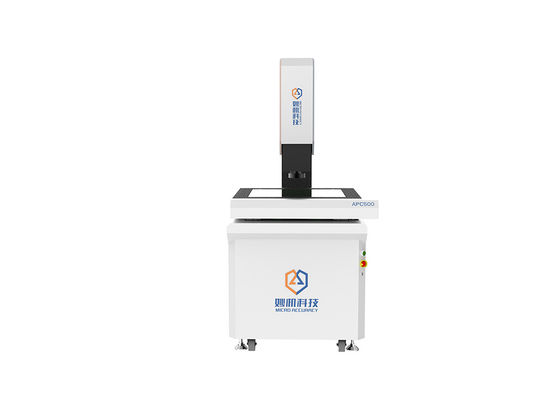

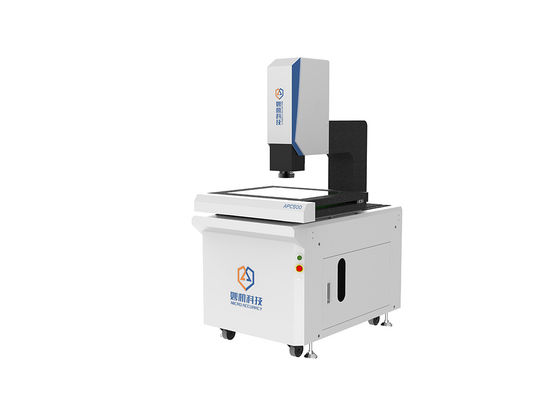

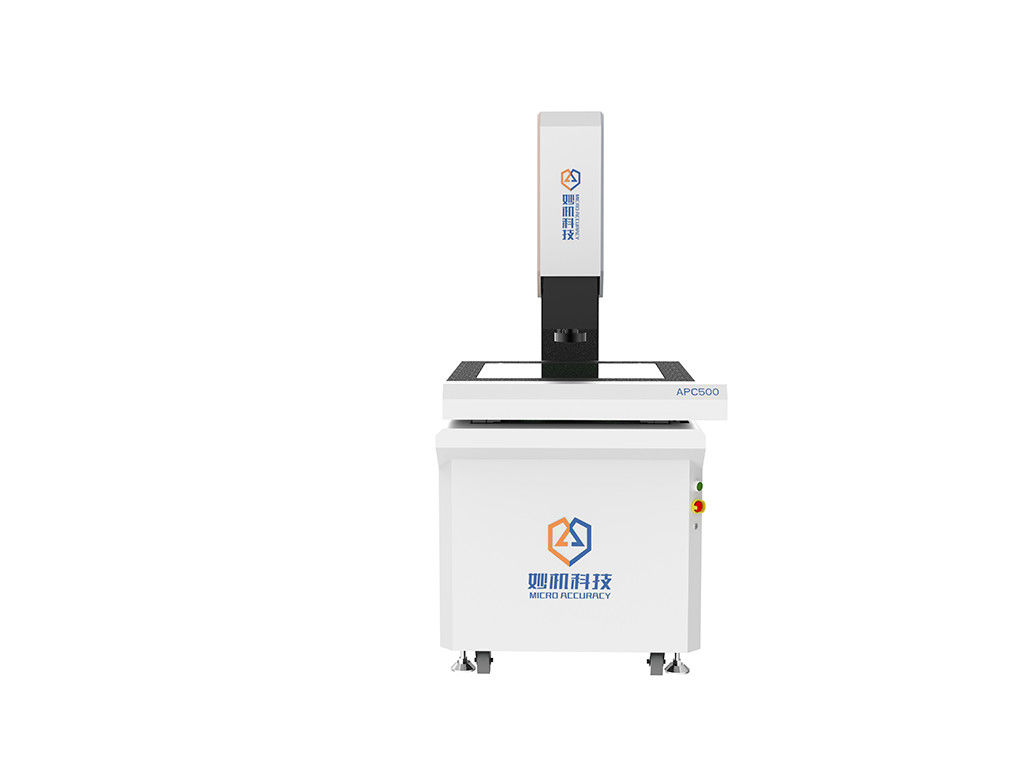

2D Cylindrical 190X CNC Video Measuring System

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | MICRO ACCURACY |

| Certification: | CE ISO |

| Model Number: | APC500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Piece |

|---|---|

| Price: | negotiation |

| Packaging Details: | Standard Exporting Package |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500PCS/Year |

|

Detail Information |

|||

| Magnification: | 27X-190X | Operation Method: | Automated |

|---|---|---|---|

| Kind Of Light Source: | LED Transmitted And Reflective Light | Travel-X.Y Axis: | 500*400(mm) |

| Travel-Z Axis: | 200 | Repeatability: | 0.003mm |

| Stage Load Capacity: | 20kg | ||

| High Light: | 255X CNC Video Measuring System,190X CNC Video Measuring Systems,190X Cylindrical optical metrology equipment |

||

Product Description

2D Cylindrical 190X CNC Video Measuring System

APC500 CNC Video Measuring Systems

Highly precise, automatic measurement of various types of precision equipment and electronic components.

Usage

APC series automatic video measuring machine is widely used in precision machinery, electronics, instrumentation, plastics, automobiles, mobile phone tablets, precision molds, LCD, LED display, PCB and other industries.

Features

■ High-precision marble base, table and column to ensure high stability and rigidity

■ TBI grinding grade ball screw

■ Panasonic full-closed-loop servo motor, speed can be adjusted

■ Programmable 5-ring 8-zone annular surface light to meet different angle lighting requirements

■ Optional HEIDENHAIN high-precision non-touch grating

■ Fully automatic zoom lens, no need re-calibrate when changing magnification, save calibration time and avoid human error

■ Optional Renishaw contact probe for height, depth and other 3D measurement

■ Optional THK precision guide and ball screw

■ Optional customization lifting illumination, product outline display is clearer, and grabbing is more precise

■ Optional KEYENCE laser displacement sensor for roughness, flatness surface measurement

Technical data

| Model | APC300 | APC400 | APC500 | ||

| X,Y axis travel(mm) | 300*200 | 400*300 | 500*400 | ||

| Stage glass size(mm) | 357*257 | 457*357 | 557*457 | ||

| Z axis travel(mm) | 200 | ||||

| X,Y,Z axis resolution (μm) | 0.5 | ||||

| Length unit | Linear scale | ||||

| Measuring accuracy (μm) | 2.5+L/200 L=measuring length (mm) | ||||

| Operation mode | CNC | ||||

| Image kit | High resolution CCD camera | ||||

| Detent zoom lens | 0.7X~4.5X | ||||

| Video magnification | 23X~190X | ||||

| Object of view | 10.6mm~1.6mm | ||||

| Working distance | 90mm | ||||

| Measuring software | CNC 2D | ||||

| Illumination | Transmitted | LED programmable ring light | |||

| Contour | LED parallel contour light | ||||

| Power supply | AC100~240V 50/60Hz | ||||

1. Establish the quality management system based on ISO9001, improve quality inspection, and ensure that all the finished products are qualified.

2. All our measuring machines are with CE certification

3. All our measuring machines are assembled and adjusted with linear accuracy, so that the instrument accuracy is guaranteed by hardware assembly and adjustment to the greatest extent.

4. We has provided professional and complete measurement solutions for many large and medium-sized enterprises at home and abroad, and

has won the trust of customers!

5. Our professional technical service team is familiar with the principle, structure, assembly, and software debugging of the instrument, freeing customers from worries!

After-sale Service

1. Free professional operation training

2. Warranty: 18 months instead of 12 months

3. Regularly upgrade of software is available free

4. Lifetime maintenance

Machines are ready for dispatch

![]()

![]()

![]()

![]()

![]()